Our process modeling program in the Scale-up Suite lets you accomplish these targets and speed up process development though addressing ever more intricate processes.

Obtain insight into reaction mechanisms for deep response being familiar with that can be leveraged for ideal processing

Backed by our superb person assistance and schooling, Scale-up Suite empowers providers to achieve deep process know-how and attain productive manufacturing in their items.

Scale-up Suite�?is a number one provider of process enhancement application for the worldwide pharmaceutical and chemical industries.

Use mechanistic designs to predict problems that maximize produce and decrease impurities in artificial organic processes

Forecast the overall performance of each unit Procedure ahead of Each individual campaign to ensure results on scale-up from lab to plant.

Transferring a process across scales will normally effect the Actual physical charges within the synthesis, which include mixing, warmth transfer, and mass transfer. Comprehending the affect of these prices on the process is important to planning the process to function efficiently and robustly when creating high-quality goods at new scales.

Promptly develop response kinetic products from chemical intuition and customary lab data to layout optimal reactions.

Our process modeling software in the size-up Suite delivers a simple-to-use and comprehensive platform for building calculations and performing simulations which can account with the Actual physical rates, making certain a suitable to start with time scale-up and effective tech transfer.

We've been dedicated to continuing to deliver the superb solutions and consumer help that our clients have arrive at be expecting from Scale-up Programs and anticipate adding the global strengths of METTLER TOLEDO.

Process calculations and simulations that can be applied throughout all scales, enabling accelerated development and correct initially time scale-up.

The mix of our greatly used Scale-up Suite�?process enhancement and scale-up program with METTLER TOLEDO's marketplace-main products and services for read more biological and chemical process development results in by far the most detailed offerings for these critical programs from the pharmaceutical and chemical field.

Mixing calculation equipment support scale from lab reactors for example Ambr® fifteen, shake flasks, vials, and rocked/wave baggage to stirred tank reactors

Like a chemical process is created, extra content have check here to be made to eventually accomplish commercial production requires.

METTLER TOLEDO is dedicated to not merely keeping carbon neutrality for our operations and also to creating science-primarily based targets to push an complete Biodiesel refining unit reduction of greenhouse gas emissions throughout our operations and provide chain.

Comprehensive library of Completely ready-to-use simulation resources formulated by read more industry gurus, readily available to all consumers

Immediately remodel routinely collected process, PAT, and offline analytical information into kinetic versions that help increased response comprehending with minimal time and components

Acquire bioreactor styles to aid the prediction of glucose and DO amounts, pH, and titer at Each individual scale, leveraging mixing tools to make certain uniform read more spatial distribution

Search a personalized portfolio, obtain quotes, and handle your installed devices on our extended digital System.

Process scale-up commonly refers to raising the production potential by running a chemical process in larger sized equipment. For instance, transferring a process from your lab scale to your pilot plant or from a pilot plant to an entire-scale production plant.

Usually, a chemical process is scaled up quite a few times, over orders of magnitude, from compact lab bench scale to medium pilot plant amenities to significant whole-scale production vegetation.

Make certain satisfactory mixing with no abnormal shear in operations ranging from media enhancement/prep to UF/DF, averting batch failures and produce loss

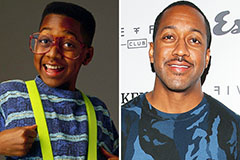

Jaleel White Then & Now!

Jaleel White Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Traci Lords Then & Now!

Traci Lords Then & Now!